GANZ is one of the first shipbuilding companies in the world that the mass production of a wide range soil carrying hopper barges for the transport of ground raised by conventional and / or milling dredgers. The principle of the hopper barge is a vessel consisting of two halves, cranks relative to each other on the hinges. Hinges on both sides are connected to the hydraulic cylinders. When passing the housing halves barge divided longitudinally and load reset spontaneously due to the shape and design of the vessel. After unloading the housing halves are moved back together due to the shape and structure, and rods retract cylinders.

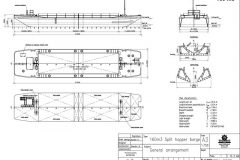

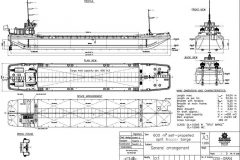

- 160 m3 capacity split barge

- 160 m3 capacity detachable split barge

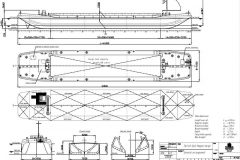

- 200 m3 capacity split barge

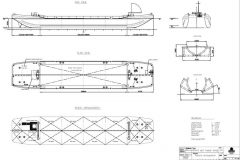

- 240 m3 capacity split barge

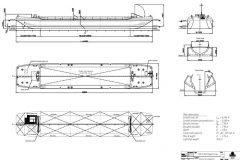

- 315 m3 capacity split barge

- 320 m3 capacity split barge

- 335 m3 capacity split barge

- 450 m3 capacity split barge

- 600 m3 capacity split barge

- 600 m3 capacity self propelled split barge

Typical lineup of barges presented by vessels:

- For inland waters (river performance): towed barges with capacity from 40 up to 1000 m3 (80-1900 tons); self-propelled barges with a volume of 600 to 1000 m3 (1100-1900 tons).

- Marine performance (coastal): towed barges with capacity from 160 to 1000 m3 (300-1900 tons); self-propelled barges with a capacity from 600 to 2800 m3 (1100-5200 tons).

- Marine performance (open sea): towed barges with capacity from 600 to 1000 m3 (1100-1900 tons); self-propelled barges with a capacity from 600 to 2800 m3 (1100-5200 tons).

There is possible to produce a larger capacity barges too. Some typical models of barges have a mobile prefabricated modular structure that allows them to transport disassembled road and collect directly at the place of use. In accordance with the characteristics of the extracted underwater soil, barges can be equipped with a large amount of various dredgers dredging: from the grab crane to suction snapper with milling and mill-hydraulic rippers. All barges have radio control, and scows have full autonomy or the watch-interchangeable design. Soil carrying hopper barges are widely used in hydraulic engineering, dredging and drainage works, underwater construction and work on the development of the resource base of the sea shelf.